|

Brick/Block Size |

9" x 4" x3",10" x 5" x3",8" x 4" x4" |

|

Brick Raw Material |

Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

|

Usage/Application |

For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

|

No. Of Bricks Per Stroke |

4, 6, 8, 10,12, 14, 16 Pcs |

|

Pallets Size |

22" x 23" x 19mm (Thickness) |

|

Automation Grade |

Semi or Fully Automatic |

|

Brick/Block Type |

Solid, Interlock, Hollow, Paver |

|

Method |

Hydraulic Pressure |

|

System |

PLC Controlled |

|

Capacity(Blocks/Bricks ) |

1000-4000 pcs per hour |

|

Capacity per 8 Hours |

6000pcs to 40000 pcs |

|

Voltage |

440 Volt |

|

Space Required |

30 ft ( L) x 25 ft (W) x 16 Ft (H) |

|

Total Power Required |

22 HP to 50 HP |

|

Material |

Mild Steel |

|

Accessories |

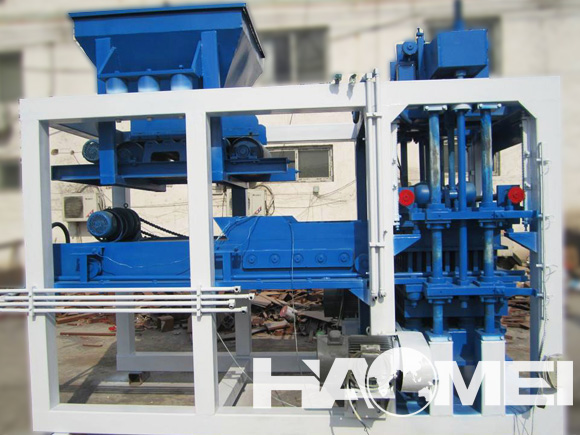

Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

|

Treatment Time of Bricks/Blocks |

Minimum of 7- 8 Days |

|

Brick/Block Size |

9" x 4" x3",10" x 5" x3",8" x 4" x4" |

|

Brick Raw Material |

Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

|

Usage/Application |

For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

|

No. Of Bricks Per Stroke |

4, 6, 8, 10,12, 14, 16 Pcs |

|

Pallets Size |

22" x 23" x 19mm (Thickness) |

|

Automation Grade |

Semi or Fully Automatic |

|

Brick/Block Type |

Solid, Interlock, Hollow, Paver |

|

Method |

Hydraulic Pressure |

|

System |

PLC Controlled |

|

Capacity(Blocks/Bricks ) |

1000-4000 pcs per hour |

|

Capacity per 8 Hours |

6000pcs to 40000 pcs |

|

Voltage |

440 Volt |

|

Space Required |

30 ft ( L) x 25 ft (W) x 16 Ft (H) |

|

Total Power Required |

22 HP to 50 HP |

|

Material |

Mild Steel |

|

Accessories |

Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

|

Treatment Time of Bricks/Blocks |

Minimum of 7- 8 Days |

InquiryPlease feel free to submit your inquiry information to us.